How does SiC provide Power for "new infrastructure"

On March 4, on the meeting of the Standing Committee of the Political Bureau of the CPC Central Committee, Policymakers stressed that it needed to accelerate major projects and infrastructure construction that have been defined in the national plan, including the construction of new infrastructure such as 5G networks and data centers -- This short sentence makes "new type of infrastructure construction" become a hot word again.

New infrastructure construction is committed tobuild the science and technology infrastructure construction, mainly contains 5g infrastructure, uhv, inter-city high-speed railway and inter-city rail transit, new energy automobile charging pile, large data centers, artificial intelligence, industry Internet, total seven areas,which involve communication,electric power, transportation, digital and other social livelihood keyindustries.

SiC is a representative of the third generation of semiconductor materials.In terms of silicon, the current Si MOSFETapplication is mostly below 1000V, about 600—900V, if more than 1000V, its chipsize will be very large, switching loss, parasitic capacitance will also increase.The advantages of SiC devices over Si devices are lower energy loss,easier miniaturization, and greater heat resistance.

SiC power devices are mainly located in scenarios with power between 1kw and 500kw and operating frequency between 10khz and100mhz, especially for some applications requiring higher energy efficiency andspace size. For example, in the fields of electric vehicle on-boardcharger and electric drive system, dc charging pile (quick charging pile),photovoltaic micro-inverter, high-speed rail, smart grid and industrial-gradepower, it can replace some silicon-based MOSFET and IGBT.

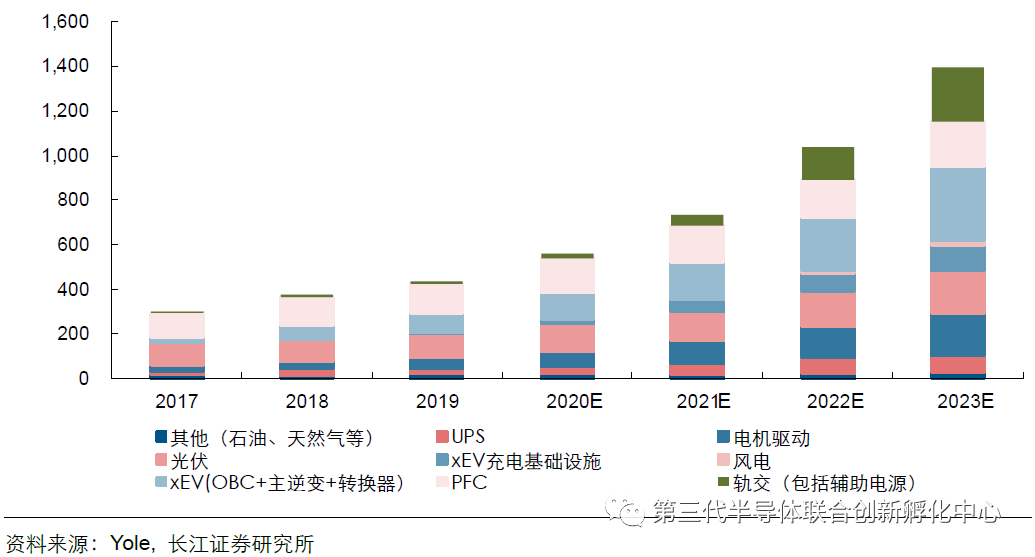

▼ Application areas and their market space of SiC(million dollar)

According to IHS,the global SiC power device market space is about $399 million in 2017,and the overall demand scale is expected to grow at a compound rate of about26.6% from 2017 to 2023. Global demand is expected to reach $1.644 billion in 2023.The main down stream application scenarios include UPS power supply,electric vehicle, charging pile, motor, photovoltaic, rail crossing, aerospaceand military industries. Among of them, electric vehicle, charging pile andother fields have strong growth, and the CAGR is expected to reach81.4%/58.0%.In addition, UPS, photovoltaic and other market space are also relatively larger.

▼ Cree released SiC capacity expansion plan forMay 2019

Source:Cree, Astroys, research and development department, citic construction investment securities

EV: the commercial use of the model is gradually started, and the growth momentum is sufficient. Tesla Model3 starts to adopt STM customized SiC-MOSFET with parameter of 650V / 100A. Each Model3 is equipped with 24 650V / 100A SiC-MOSFET modules, with 2 SiC chips in each module inparallel.

▼TeslaModel3 inverter structure

Source: TeslaModel3 power system (main inverter) analysis (ii)(Yang yixuan)

Combined with the application of Model3 for MOSFET (SiC) (STMmatching), considering the system economy of battery cost, magnetic material cost and other costs brought by using MOSFET (SiC), it is estimated that usage of MOSFET (SiC) can obtain positive economy on unit cost of the system when the battery capacity reaches 75kWh.If the cost reduction rate is combined with different SiC-MOSFET, the economy of SiC-MOSFET on system cost is expected inthe next 3-4 years under the neutral hypothesis.

On Feb. 28, BYD unveiled a high-performance SiC - MOSFET control module developed and manufactured by the company. According to news reports,BYD's SiC module will be mounted on byd's han EV model, which will reduce internal resistance, increase the over-current capacity of the electriccontrol system and significantly increase the power and torque of the motor. Currently,the world's leading EV host manufacturers are fully accelerating the commercial application of SiC devices in specific models.

Rail transit:significant energy efficiency advantage

The rail transit industry is also one of the main application industries of silicon carbide power devices.The future rail transit puts forward higher requirements for power electronic devices, such as traction converter, power electronic voltmeter,etc.The power density and working efficiency of these devices can be greatly improved by using silicon carbide power devices.At present,subject to the current capacity of silicon carbide power devices, the silicon carbide hybrid module will first replace some silicon IGBT modules.In the future, with the increase of the capacity of silicon carbide devices, all-silicon carbide modules will play a greater role in the field of rail transit.SiC devices can further achieve high efficiency and miniaturization of equipment, and have great technical advantages in rail transit.

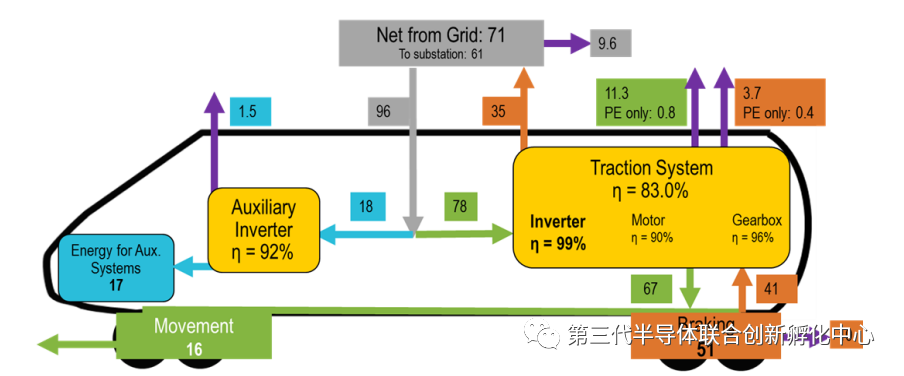

▼energy flow indc system of train using SiC-PE

Source: oak ridge national laboratory

First, SiC devices can reduce power losses from 5-6% to 2-3%.Second, the high temperature performance of SiC can reduce the

cooling system volume and the high frequency characteristic can reduce the inverter weight by 30%, thus saving 3.2-8.6% energy.Third, the high frequency also allows the inverter andengine to respond quickly, further improving efficiency.

▼ categorize the condition of power semiconductor of rail transit

Source: Yolo, citic securities research

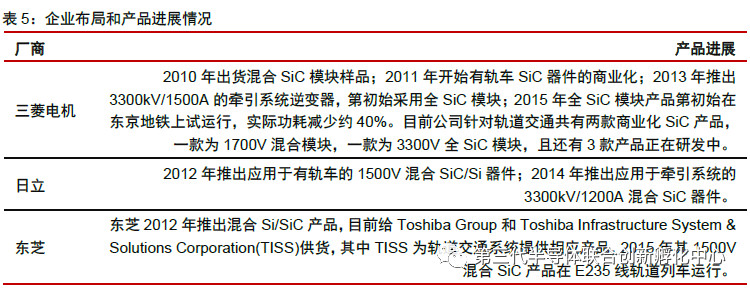

From the perspective of relevant manufacturer layout,SiC's penetration in the rail transit market is dominated by

Japanesemanufacturers, and the overall trend of transition from mixed SiC products toall-sic products is presented.

▼ enterprise layout and product progress

Source: Hitachi website, electronic media,Railwaytechnology, Powerpulse, citic securities research

Communication: 5G industrialization is pregnant with hugespace

In 2001, Infineon opened up the market for SiC powerdevices by combining 600V SiC diodes with silicon-based devices in

PFCcommunication power supply.Currently, the data center and communications power markets are the largest downstream

application markets for SiC power devices.

Communication power supply is energy library of theserver and the base station communication, which provide power for all kinds oftransmission equipment, and ensure the normal operation of communication system. Communication power supply system in the whole communication industry accounted for very small proportion, but it is the key of the whole communication network infrastructure, which is a complete and an irreplaceablekey component.

The high frequency characteristic of SiC-MOSFET makes themagnetic unit in the power supply circuit smaller and lighter, and the"zero" characteristic of SiC-JBS reverse recovery time makes the switching loss of the circuit greatly reduced, which has a huge advantage prospect in data center and communication power supply.

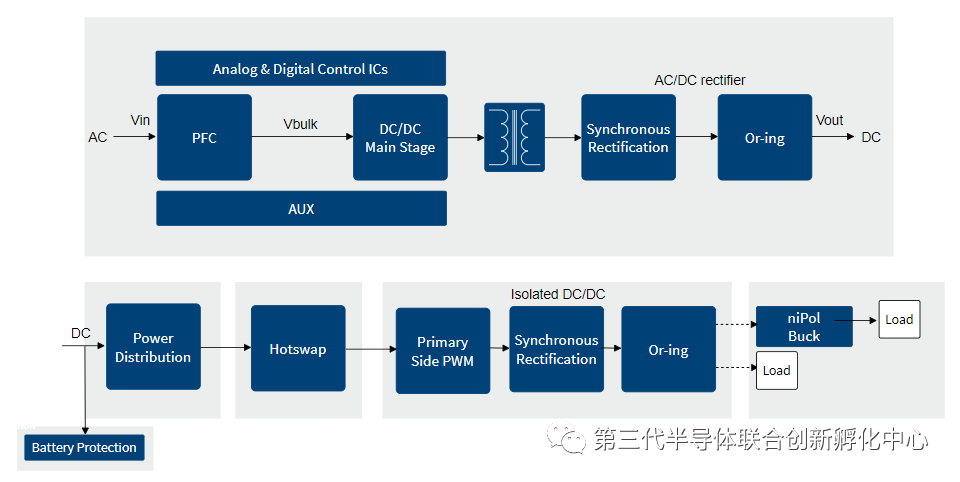

Among them, the communication power supply is mainly composed of three parts: controllable PFC, inverter and rectifier. Taking Wolfspeed as an example, it adopts 6 SiC-MOSFET modules of 1200V/50A in PFC.

▼The communication power supply mainly consists of controllable PFC, inverter and rectifier

Source: infineon

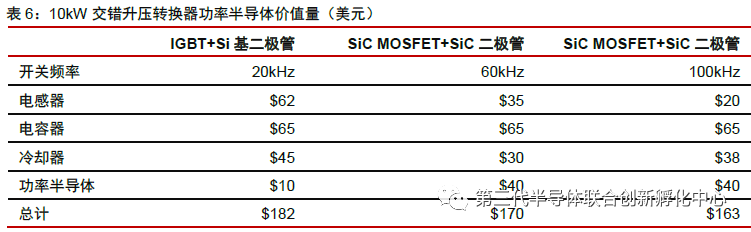

According to Richardson RFPD, the power semiconductorvalue of the 10kW stagger boost converter is shown in the following table, andthe SiC device consumption is basically $160-170.

▼10kW staggered boost converter power semiconductor value ($)

Source: RichardsonRFPD, citic securities research

It is estimated that from 2020 to 2028, the Chinesemarket alone will drive the construction of more than 4.5 million base stationsin the 5G industrialization, with huge potential demand.

▼estimation of the collective procurement scale of China's 5G base stationfrom 2019 to 2028 (10,000 stations)

Photovoltaic: the full life cycle advantage is obvious,the rate of cost reduction will deeply affect the initial investment

At present, the photovoltaic industry is the secondlargest application market of SiC power devices, accounting for more than 30%

of the SiC power device market.SiC photovoltaic inverter efficiency can reachmore than 99%, energy conversion loss can be

reduced more than 50%, can greatly reduce the cost and volume of the inverter.

Photovoltaic inverter is continuously developing towardsthe direction of high efficiency, high reliability and high power density,while SiC power devices can generate power more efficiently by relying on loweron-off conductivity, switching loss and no current trailing phenomenon ofsi-based devices.Higher efficiency of SiC can reduce loss, reduce temperature cycle, improve

device life, and achieve safety and reliability.Higher switching frequency reduces the volume of passive device and reduces the volume and weightof inverter.Full life cycle Angle saves investment.

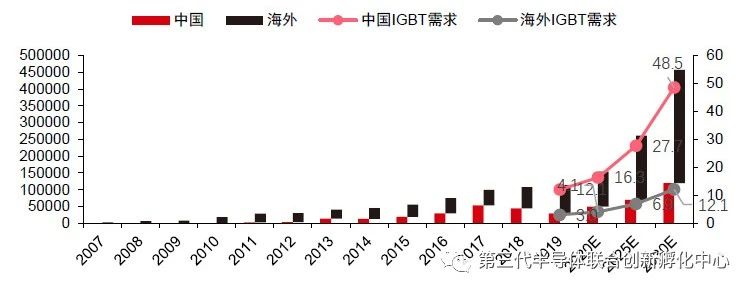

▼ new installed pv capacity (MW, left axis) and IGBTpurchase demand (100 million yuan, right axis) in China and overseas markets

Over the pasttwo years, photovoltaic (PV) inverter market has experienced the acceleration of IGBT/SiC composite booster module, and began to gradually application of theSiC module in 2019, now the main factor of restricting the large-scaleapplication of SiC power devices, is still high initial purchase cost ledby the SiC prices , which is expected to gradually improve with SiC decline inunit costs.